Tránh thai

Bài Viết Xem Nhiều Tránh thai

- Tiêm Thuốc Tránh Thai An Toàn Không, BS Trả Lời Update 04/2024

- Thắt Ống Dẫn Tinh Như Thế Nào, Có Nối Lại Được Không, Ưu Nhược Điểm Update 04/2024

- Biện Pháp Cấy Que Tránh Thai Và 5 Lưu Ý Từ Bác Sĩ Update 04/2024

- Tiêm Thuốc Tránh Thai Cho Nam Giới – Tại Sao Không? Update 04/2024

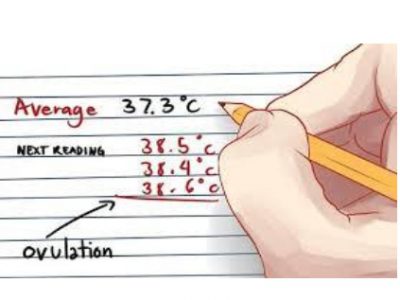

- Mách Bạn 5 Cách Tính Ngày Rụng Trứng Để Tránh Thai Hiệu Quả Update 04/2024

- Tránh Thai An Toàn – Chuyện Không Nhỏ, Hậu Quả To Update 04/2024

- Tìm Hiểu 20 Cách Tránh Thai Cho Nữ Giới 90% Chị Em Bỏ Qua Update 04/2024

- Miếng Dán Tránh Thai, Ưu Nhược, Biến Chứng Và Những Điều Cần Lưu Ý Update 04/2024

- Thắt Ống Dẫn Trứng – Hiểu Không Đủ Dễ Dẫn Đến Nuối Tiếc, BS Cho Hay Update 04/2024

- Cách Dựa Theo Chu Kỳ Kinh Nguyệt Để Quan Hệ, Tránh Thai An Toàn Update 04/2024

Sự phát triển của thai nhi

Bài Viết Xem Nhiều Sự phát triển của thai nhi

- Chỉ Số BPD Là Gì? Chỉ Số Phát Triển Này Quan Trọng Với Thai Nhi Như Thế Nào? Update 04/2024

- Thai Nhi Có Đường Kính Lưỡng Đỉnh Lớn Có Sinh Thường Được Không? Update 04/2024

- Quá Trình Phát Triển Của Thai Nhi 9 Tuần Tuổi Update 04/2024

- Cách Tính Tuổi Thai Theo Tuần Và Tháng Một Cách Chính Xác Update 04/2024

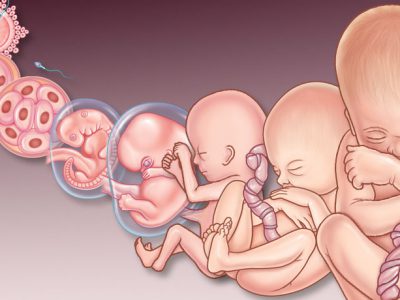

- Sự Phát Triển Của Thai Nhi Qua Từng Tuần Update 04/2024

- Đường Kính Lưỡng Đỉnh Thai 37 Tuần, Thai Nhi Phát Triển Như Thế Nào? Update 04/2024

- Quá Trình Phát Triển Của Thai Nhi 11 Tuần Tuổi Chi Tiết Update 04/2024

- Quá Trình Phát Triển Của Thai Nhi 17 Tuần Tuổi Chi Tiết Update 04/2024

- Quá Trình Phát Triển Của Thai Nhi 26 Tuần Tuổi Chi Tiết Update 04/2024

- Quá Trình Phát Triển Của Thai Nhi 25 Tuần Tuổi Chi Tiết Update 04/2024

Mang thai

Bài Viết Xem Nhiều Mang thai

- Làm Sao Để Nhận Biết Dấu Hiệu Có Thai Sau Chuyển Phôi Chính Xác 80% Update 04/2024

- Độ Mờ Da Gáy Từ 1.6mm, 1.7mm, 1.8mm, 2mm, Đến 3mm Có Nguy Hiểm Update 04/2024

- Ra Máu Khi Mang Thai Tháng Cuối, BS Cho Biết Điều Gì Update 04/2024

- Dấu Hiệu Mang Thai Con Trai Chuẩn Từng Centimet Mẹ Đã Biết Update 04/2024

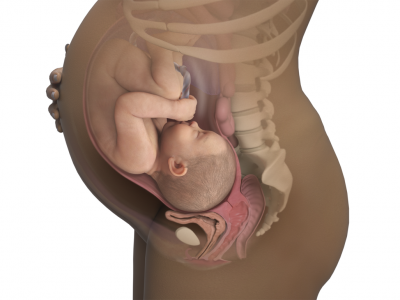

- Những Dấu Hiệu Sắp Sinh Mẹ Bầu Nhất Định Cần Chú Ý Update 04/2024

- Những Vật Dụng Quan Trọng Không Thể Thiếu Khi Đi Sinh Con Vào Mùa Đông Update 04/2024

- Đường Kính Lưỡng Đỉnh Thai 37 Tuần, Thai Nhi Phát Triển Như Thế Nào? Update 04/2024

- Hội Chứng HELLP: Nguyên Nhân, Triệu Chứng, Chẩn Đoán Update 04/2024

- Đa Ối Có Sinh Thường Được Không? BS Trả Lời Update 04/2024

- Quá Trình Phát Triển Của Thai Nhi 11 Tuần Tuổi Chi Tiết Update 04/2024